Who Can We Assist?

The DIN7 production center can be of assistance to anyone who is developing a product: Engineers, mechanical & material engineers, Product developers, Industrial designers & entrepreneurs. All can enjoy access to the industry’s finest 3D print technologies and equipment, now more than ever. We serve a wide variety of industries from traditional to unusual, and can facilitate projects of different scales from functional models and initial prototypes to end-use production parts. Whatever the project is, our goal is combining our passion for 3D printing and our professional expertise to an outstanding customer experience.

Who Can We Assist?

MJF- Multi Jet Fusion

Suited for:

Medium production series, Engineering parts, Aviation parts, Medical use

Industries:

Aviation, Medical, Robotics

Materials:

This method is much faster than other types of 3D printing and creates much stronger parts without adding excess weight. It is also more precise than other types of 3D printing, making it ideal for creating intricate pieces such as precision tools or delicate models.

SLS- Selectiv Laser Sintering

Suited for:

Medium production series, Engineering parts, Aviation parts, Medical use

Industries:

Aviation, Medical, Robotics

Materials:

SLS is a powder-based 3D printing technology considered to be a great solution for the rapid manufacturing of functional polymers because it offers a very high degree of design freedom, high accuracy and high resistance including over time and durability under significant changes of temperature. SLS produces parts with good and consistent mechanical properties which means it can be used to produce parts that are very close to end-use quality, so you can use it throughout the production process, from concept to trial models. SLS also enables lowering printing costs radically, an attribute that made it a groundbreaking technology that changed the rules of the game and the way we print 3D.

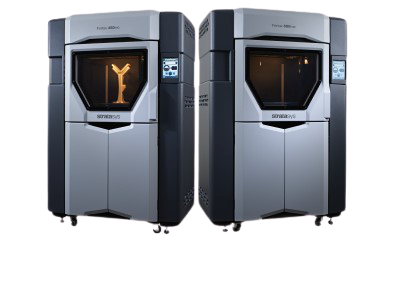

FDM - Fused deposition modeling

Suited for:

Medium production series, Engineering parts, Aviation parts, Medical use

Industries:

Aviation, Medical, Robotics

Materials:

FDM Technology works with specialized 3D printers and production-grade thermoplastics to build strong, durable and dimensionally stable parts with the best accuracy and repeatability of any 3D printing technology. Parts printed with FDM technology are known to be highly resistant and therefore FDM is widely used for printing end-products which need to withstand the toughest standards and regulations. FDM printers vary at price and capability. DIN7 production center proudly owns the Fortus 450 printer, the superman of FDM printers. The Fortus 450 broadens our ability to print highly complex parts for various applications that need to withstand extreme environmental conditions

DLP - Direct light projection

Suited for:

Exhibition models, Plastic injected models, Casting molds

Industries:

Materials:

DLP printing technology utilizes light and a liquid resin to make solid parts and products. DLP enables a very detailed resolution print and dimensional accuracy. The quality of the printed surface makes it possible to dye it in a way that will resemble the end-product in the most precise way. Another prominent advantage of DLP is printing speed,which can save any project a substantial amount of time. Its advantages make DLP a preferable choice for small parts which require delicate, precise, and detailed visual display

Additional post-process services

Dyeing & painting

DIN7 offers a range of dyeing techniques according to your and your product’s needs, its usage and application. Hydro dipping, Wet printing, MIL-STD painting, special dyeing and masks.

Inserts

The DIN7 team will help you define the ideal inserts for your product, bringing out the best out of your vision and creating the finest and strongest product possible.

Standardization

If requested, DIN7 can deliver you a dimension report, a First Article Inspection (FAI) and a certificate of standardization.

Surface texture

As part of our service for parts printed via SLS or FDM techniques, DIN7 offers the Trommel machine for surface smoothening.

Coatings

DIN7 offers various coating solutions including UV coating for products exposed to various weather conditions, ensuring your product’s durability.

Our Work

Team up with DIN7’s engineering & product design task team and together we will optimize your vision all.